MATERIALS:

Many option valve materials

are available.

|

SS 316 |

SS 304 |

ALLOY - 20 |

44OC |

|

CERAMIC |

GLASS |

TITANIUM |

MONEL |

OPTIONS:

VOLTECH develops a wide variety of

pump heads and adjustment options which makes VIP metering pumps truly versatile.

ACCESSORIES:

Avilable a safety valve, Strainer, Back Pressure Regulator,

Pressure Systaining valve, Calibration pot, Pulsation Dampener.

SPECIAL FEATURES:

Accuracy - Totally enclosed, water and dust proof housing - wide

capacity range - fully automatic lubrication - compact - light weight - wide

range of heads - multiplexing choice of different type and capacities can be

achieved by multiplexing - easy avilability of spares - before shipment, each

pump is fully tested and approved to perform to exact

requirements.

THE

ADVANTAGES:

- Oil immersed operating

assemblies for continuous operation. - Automatic gas venting of hydraulic

oil.

- Variety of check valves designs for difficult liquids.

- Special

'U' spring loaded seals.

- Relief and replantig valve in hydraulic

circuit.

- Relatively better resistance to fouling.

- Long working life to

PTFE Diaphragm and gentle flow against the diaphragm.

Application:-

- Chemical

processing :- Refinery, Petrochemical,

Fertilizer pulp and paper, Rubber and latex.

- Water and west water

treatment :- Polelectrolite,Flocculants,Alum dosing,Chlorine

solution.

- Food & Beverages :- Sugar solution, vitamins,

proteins, Flavours, Acetic & latcic acid.

- Pulp & Paper :-

Dyes, Resins, paper whiteners.

- Oil & Gas :- Methanol,

Mercaptons and Inhibitors.

- Power Generators :- Conditioning of

water, Water degassing & degreasing.

Mechanically Flexed

Diaphragm

Type Diaphragm Type

Diaphragm Type Plunger Type

|

|

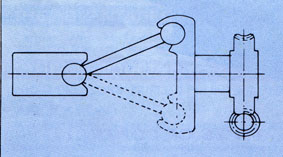

PRINCIPLE:-

VIP Dosing/metering pump is precise volumetric control metering

pump for feeding, measurement and control system. It is positive return type

plunger.Diaphragm pump where flow can be adjusted from 0 to 100% while the pump

is running or at rest by stroke changing mechanism. Reciprocating motion to

achieve desired fluid control by stroke setting micrometric manual adjustment or

pneumatic or elecrical actuators.

THE DESIGN:-

VIP unique design for

accurate dosing the plunger stroke length must be adjustable with almost

precision from ZERO to 100% of maximum of stroke length in power end mechanism

most important design for accuracy is connecting ball joint with piston and eccentric disc. variations in the discharge capacity are by micro-mereic

adjustment or pneumatic or electrical.

ZERO

STROCK

High rotary motion is

transmitted by craft make high speed worm to wheel in a perpendicular plane, the

crank disc also revolves in the perpendicular plane which eliminates

reciprocating action in the cross head and plunger rendering the pump to a zero

stroke.

FULL OR PARTIAL STROKE

For 100% or

at any internal stroke setting worm gear is adjusted away from the perpendicular

plane i.e. the eccntric disc move back off the perpendicular axis. As the

connecting ball joint transmits a reciprocating motion to the crosshead and

plunger. In such position the pump is at 100% or at partial stroke setting as

the case may be stroke length adjustment by changing the radius of the

reciprocating crank eneuides near harmonic motion for the plunger travel at all

stroke length the ball checks on suction and discharge are synchronized to

respond resulting in to efficient operation of the pump.

VALVES:-

Metering pump check valves

are heart of the pump performance, Precision and accuracy depend on the correct

shape and design to suit for known Fluid characteristics.

In

addition to above , VIP has special designs of value

like:

1. Slurry valves

2. High Viscocity valves

3. Soft seal valves

4. Special Metal Valves

5. Inverted Design

Valves.